Xuzhou Elsen Machine Tool Co., Ltd

VMC850

Publish time 2020-04-22 16:05

FEATURES:

CNC system controller

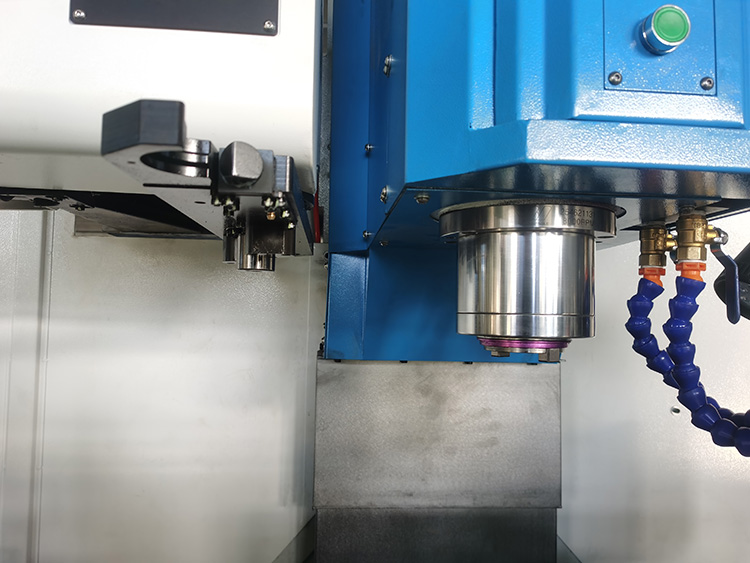

High quality machine baseTaiwan famous brad spindle

Taiwan famous brand ball screw

High pressure cylinder

Taiwan linear railway

Japanese bearing

Automatic lubrication system

The fourth axis and Chip conveyor at optional

VMC cnc machine centers can realize the clamping of various parts such as discs, boards, housings, cams, and molds at one time. It can be used for drilling, milling, boring, expanding, reaming, rigid tapping, etc. The production of medium and small batch products can satisfy the processing of complex and high-precision parts. The fourth rotary shaft can be equipped to meet the processing requirements of special parts.

Specifications | Units | VMC850 |

Table size | mm | 1000x500 |

X axis travel | mm | 800 |

Y axis travel | mm | 500 |

Z axis travel | mm | 500 |

Max. worktable load | kg | 500 |

T slot(number-width-pitch) | 5-18x100 | |

Max. spindle speed | rpm | 8000(Optional:10000 ) |

Spindle taper | mm | BT40 |

Main motor power | kw | 7.5/11 |

X/Y/Z rapid traverse speed | m/min | 24/24/20 (Optional:48/48/36 ) |

Cutting feed speed | mm/min | 1-8000 |

Guide rail type | Linear rail | |

Distance from spindle axis to column surface | mm | 525 |

Distance between spindle nose and worktable surface | mm | 130-630 |

Positioning accuracy | mm | ±0.0075 |

Repeat positioning accuracy | mm | ±0.005 |

Tool magazine | Arm 24 | |

Max. tool diameter | mm | φ78 (Adjacent)/ φ120(Apart) |

Max.tool weight | kg | 8 |

Machine weight | kg | 5600 |

Overall dimension | mm | 2600X2300X2800 |

Optional Configuration

1) FANUC 0i-MF/SIEMENS 808D/GSK system

2)Arm type tool changer

3)Screw type chip conveyor

4)Chip cart

5)4th or 5th axis

6)Metrol tool setters

7)Transformer to suit local power supply

Address:

2-918,High Speed Rail Times Plaza,Economic Development Zone,Xuzhou City, Jiangsu Province

email:

info@elsencnc.com

contact number:

86-516-83661968

Copyright © 2017 Xuzhou Elsen Machine Tool Co., Ltd