Xuzhou Elsen Machine Tool Co., Ltd

Features:

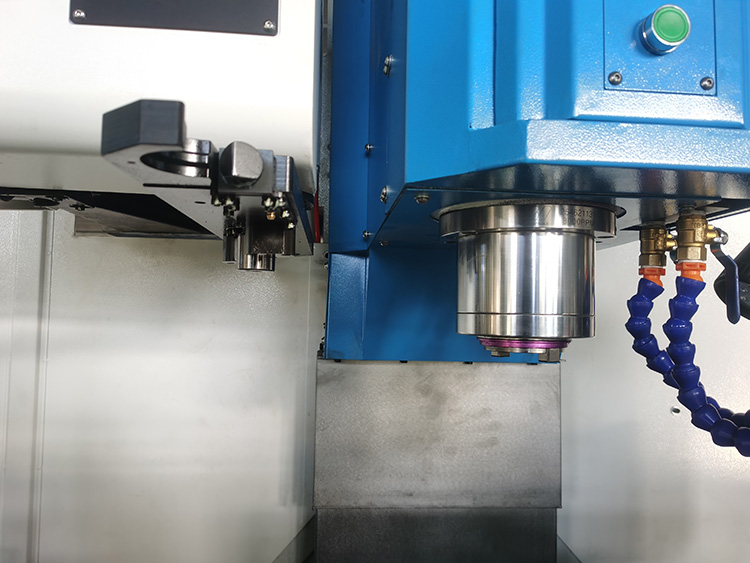

The feed axis machining center for X, Y, Z coordinate control, spindle servo motor powered,magazine capacity of 16. can achieve a

variety of disc-type, plate type, shell, Cam, mold and other complex parts in a single setup, complete the drilling, milling and processing

a variety of processes, boring, expanding, reaming, tapping,etc. suitable for many varieties, small batch production of complex,

high-precision machining of parts to better show its superiority.

Specifications

| Units

| VMC650

|

Table size

| mm

| 800x400

|

X axis travel

| mm

| 650

|

Y axis travel

| mm

| 400

|

Z axis travel

| mm

| 500

|

Max. worktable load

| kg

| 400

|

T slot(number-width-pitch)

| 3-18x125

| |

Max. spindle speed

| rpm

| 8000(Optional:10000 )

|

Spindle taper

| mm

| BT40

|

Main motor power

| kw

| 5.5

|

X/Y/Z rapid traverse speed

| m/min

| 24/24/20

(Optional:48/48/36 )

|

Cutting feed speed

| mm/min

| 1-10000

|

Guide rail type

| Linear rail

| |

Distance from spindle axis to column surface

| mm

| 469

|

Distance between spindle nose and worktable surface

| mm

| 100-600

|

Positioning accuracy

| mm

| ±0.0075

|

Repeat positioning accuracy

| mm

| ±0.005

|

Tool magazine

| 16 Armless/(Optional: Arm 24 )

| |

Max. tool diameter

| mm

| φ90

|

Max.tool weight

| kg

| 8

|

Machine weight

| kg

| 4000

|

Overall dimension

| mm

| 2400x2000x2550

|

Standard Configuration

1)KND2100M CNC system

2)16T-Funnel type tool changer

3)Taiwan linear guide ways

4)Taiwan BT40/120/8000 spindle

5)Japanese NSK bearing

6)Automatic central lubrication system with alarm

7)Taiwan ball screw and locking nut

8)Tool holder and pull stud

9)Working lamp

10)Full enclosure machine guard

Optional Configuration

1) FANUC 0i-MF/SIEMENS 808D/GSK system

2)Arm type tool changer

3)Screw type chip conveyor

4)Chip cart

5)4th or 5th axis

6)Metrol tool setters

7)Transformer to suit local power supply

Address:

2-918,High Speed Rail Times Plaza,Economic Development Zone,Xuzhou City, Jiangsu Province

email:

info@elsencnc.com

contact number:

86-516-83661968