Xuzhou Elsen Machine Tool Co., Ltd

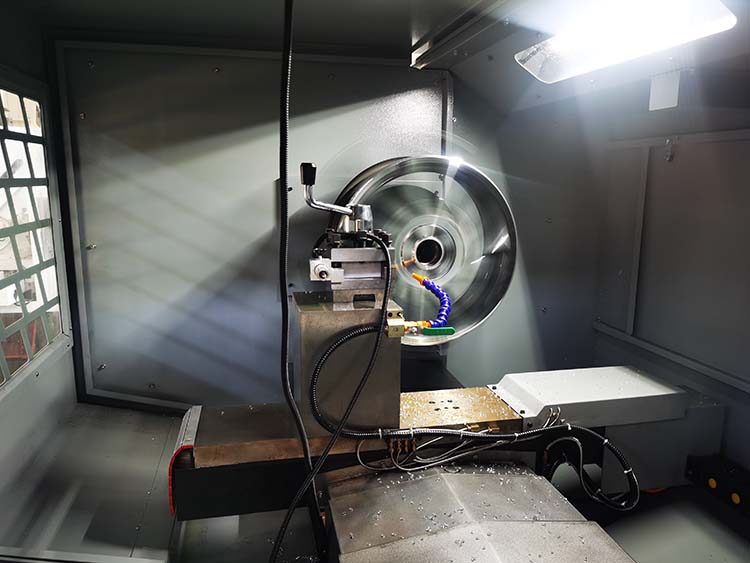

The machine tool suitable for High-precision turning and repair processing for surface of car wheel.

The machine tool has also the function of the general CNC lathes .

Just PROBE & Diamond CUT !

Once the machine has automatically probed the wheel profile, there is no need to waste time for programming our Alloy Wheel lathe. Just cut the wheel and store the profile on the system. Build up a library of Alloy wheel profiles.We save more time so you can cut more wheels!

1- Probe alloy wheel profile, transformation G code.

2- Diamond cut the wheel.

| ITEMS | AWR30 | AWR32 |

| Max. swig over bed (mm) | Φ800mm (31’) | Φ840 (33’) |

| Max. swig over cross slide | Φ550mm | Φ570 |

| Max. Size of alloy wheel | 30’ | 32’ |

| Cross slide travel (mm) | 360mm | 390 |

| Width of the rail | 400mm | 420 |

| Length of the rail | 1630mm | 1830 |

| Three-jaw chuck size | 15’ | 15’ |

| Spindle speed range (rpm) | 50~1600rpm | 50~1600 |

| Spindle speed control | Automatic | Automatic |

| Spindle bore (mm) | Φ82mm | Φ82 |

| Taper of spindle bore | 1:20/Φ 90 | 1:20(Φ90) |

| Taper of spindle nose | D1-8 | D1-8 |

| Max. size of tool post | 25×25mm | 25×25mm |

| Stations of tool carrier | 4 position | 4 position |

| Min. setting unit of motor | (Z) long 0.001mm, (X) cross 0.001mm | |

| Moving speed of post | (Z) long 8m/min, (X) cross 4m/min | |

| Motor power | 11kw | 11KW |

| Machine base | Whole cast iron base | Whole cast iron base |

| Machine size(L×W×H) | 2430*1730*2100mm | 2640×1920×2100 |

| Net weight | 3200kg | 3400kgs |

Standard Configuration:

1- 3-Jaws Chuck(With Special Soft Jaws)

2- Manual Quick Change Toolpost ,four-station turret,

3- Automatic lubrication system,

4- Turning the cooling system.

5- With probing system (TP300 Pioneer Sensing Probe TP300);

6- Diamond Cutter 1 set

7- CNC controller syntec

8- Full Enclose (Security Guard Door)

9- Specific Digital Optimization Software

10- Training Video CD

11- Work Lighting System

Address:

2-918,High Speed Rail Times Plaza,Economic Development Zone,Xuzhou City, Jiangsu Province

email:

info@elsencnc.com

contact number:

86-516-83661968