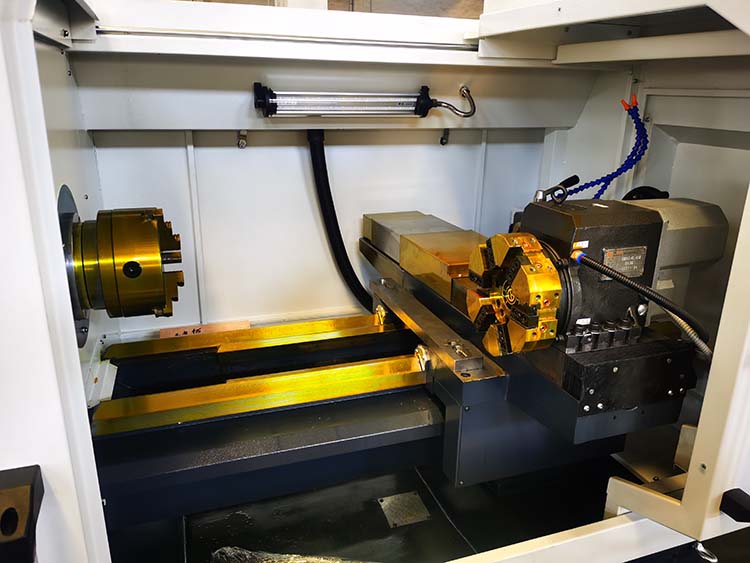

Xuzhou Elsen Machine Tool Co., Ltd

This machine could process different inner bore, ex-circle, circular conical surface and screw thread ,especially suitable for the small and middle-size shaft and plate work piece from rough processing to finish processing in batch.it has advantage like higher automaticity, simpler programming and higher accuracy.

Specification | Unit | CK6140 |

Max.swing over bed | mm | 400 |

Max.swing over cross slide | mm | 240 |

X/Z axis travel | mm | X:280 Z:550/750/1050 |

Spindle nose | A2-6 (A2-8 opitional) | |

Spindle bore | mm | 48/82 |

Bar capacity | mm | 41/65 |

Max.spindle speed | rpm | 150-2000/150-1800 |

Chuck size | mm | 200/250 |

Spindle motor | kw | 5.5/7.5 |

X/Z axis repetability | mm | 0.005 |

X/Z axis feed motor torque | N.m | X:4 Z:6 |

X/Z Rapid traverse | m/min | X:8 Z:10 |

Tailstock quill dia | mm | 60 |

Quill traverse | mm | 100 |

Quill taper | # | MT4 |

Tool post type | 4 station electric tool holder | |

Cutting tool shape size | mm | 20*20 |

Total power capacity | kva | 11 |

Machine dimension(L*W*H) | mm | 2200*1160*1620 |

Net.weight(about) | kg | 1800 |

Standard configuration:

1) System:GSK980TC3, servo motor and drive.

2) 3-jaw manual chuck.

3) Four station electric tool post.

4) Manual tailstock.

5) Cooling system.

6) Lighting system.

7) Automatic lubrication system.

Optional configuration:

1). CNC system: GSK, Siemens, Fanuc, KND, etc.

2). Hydraulic chuck, pneumatic chuck .

3). Hydraulic tailstock, pneumatic tailstock.

4). 6-station electric tool post, 8- station electric tool post, Gang type tool

5). Automatic bar feeder.

Address:

2-918,High Speed Rail Times Plaza,Economic Development Zone,Xuzhou City, Jiangsu Province

email:

info@elsencnc.com

contact number:

86-516-83661968