Xuzhou Elsen Machine Tool Co., Ltd

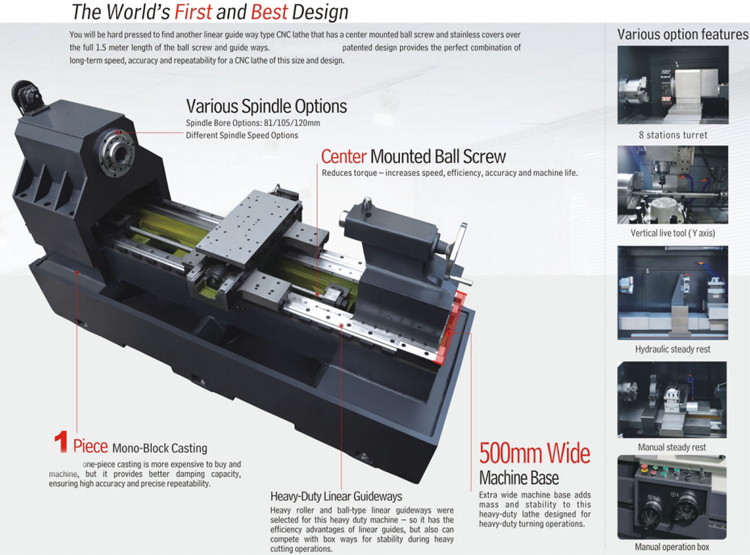

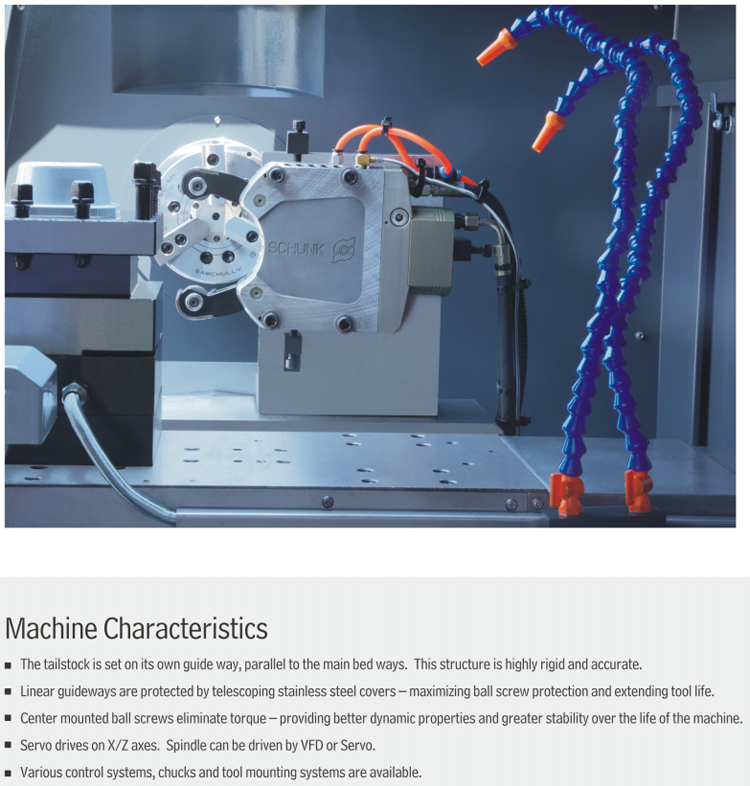

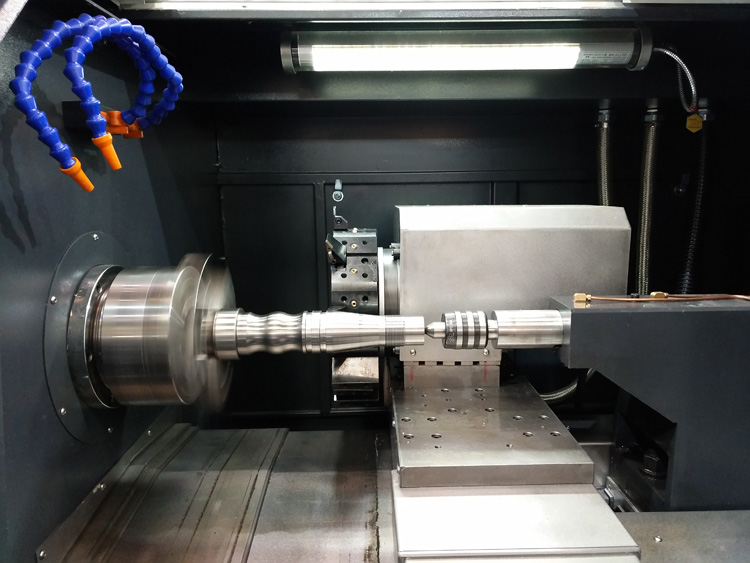

♦Linear guideways are protected by stainless steel telescoping guards for maximum protection and extending life.

♦Ballscrew are out in the middle of linear guideway without side friction torque, have a better dynamic property and are more stable over long term.

♦Servo X/Z axis motor. Spindle can be driven with a frequency inverter motor or servo motor.

♦Various control systems, toolposts, and chuck are available to configure machine for the user's individual needs.

♦The tailstock configuration is available on flat bed linear guideway structure, improving accuracy.

Specifications

Unit

Parameters

Chuck size

inch

10",Op:8"

Bed type/guideway

Flat/Linear guider

Max swing over bed

mm

φ500

Max length of workpiece

mm

1000/1500(center to center)

850/1350(chuck to center)

Op:750/1250(8/12 station turret)

Max swing over slide

mm

φ260

Spindle bore

mm

φ81

φ62

Max dia of through hole

mm

φ70

φ52

Spindle nose

A2-8

A2-6

Spindle speed

rpm

1600

2000

Op:2500

Op:3500

Op:4000

Main motor power

kw

7.5,Op:11,15

X /Z axis travel

mm

280/1000,280/1500

X/Z rapid traverse

m/min

15/15,Op:20/20

Type

4-station toolpost

Op:8-station turret

Op:gang type tooling

No.of tool stations

nos

4+2,Op:8+2

Type of tailstock

Manual,Op:Hydraulic

Taper of tailstock quill

MT5

Travel of tailstock quill

mm

100

Power capacity

KVA

15

Overall dimension(L*W*H)

mm

3400x1600x2010

Weight

kg

3600

Standard Features

|

Manual 3 Jaw Chuck |

| 4-station turret,plus gang tool plate |

| Linear guider way |

| Auto Lubrication System |

|

Auto Coolant System |

|

Tri-color Alarm light |

| Optional configurations |

| 8/12-station turret |

| Different chucks and different collets |

| Siemens/ Fanuc/Mitusbishi/GSK cnc controller |

|

Chip conveyor |

|

C axis and Live turret |

| Tool setter |

Address:

2-918,High Speed Rail Times Plaza,Economic Development Zone,Xuzhou City, Jiangsu Province

email:

info@elsencnc.com

contact number:

86-516-83661968